Acceleration Data Logger MSR165 for Fault Diagnosis of Defective Sensors

Case study Müller Martini AG

During product development of a new saddle stitcher for magazines, Muller Martini AG, a global player in the field of print finishing machines, discovered the failure of sensors. The cause of the failure was identified using small acceleration data loggers from MSR Electronics GmbH.

Author: Fabian Acklin, Technik Sammelhefter TSH-1, Mechanical Engineer Muller Martini AG

The faulty components in the three-knife trimmer for the new saddle stitcher were edge sensors which detect the position of the products immediately before they are cut. They had previously worked without malfunction, but had now failed during the test phase at customers’ premises. The analysis of the defective sensors showed mechanical damage in the sensor element.

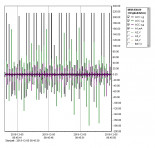

Vibrations were suspected to be the cause of the damage. However, since there were many different causes for this problem due to the very dynamic motion sequences in the machine, ways were sought to record the existing vibrations at the sensor. The aim of the measurements was to determine the possible sources of the disturbances as precisely as possible in order to draw the right conclusions. The measures implemented were also to be quickly checked for their effectiveness.

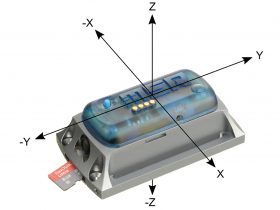

After a brief Internet search, online configuration on the website of the Swiss technology company MSR Electronics GmbH and a telephone conversation with the consultant there, the MSR165 series miniature data logger was defined as a suitable measurement device.

On troubleshooting: miniature data logger for shock and vibration

These pages might also be of interest to you:

- Configure your MSR165 shock and vibration data logger according to your needs

- Product overview MSR data loggers for the manufacturing industry

- u-blox AG: MSR165 data logger for investigating the impacts of vibrations

- Otto Bock Mobility Solutions: MSR data loggers record usage behaviour of wheelchair users

- IGR: MSR data loggers determine load values in filling plants

- MSR175plus shock data loggers monitor transport of grinding machines

Deutsch

Deutsch