CERN, European Organisation for Nuclear Research: MSR Data Loggers as Transport Detectives

CERN documents physical parameters during transports with MSR175 and MSR175plus data loggers

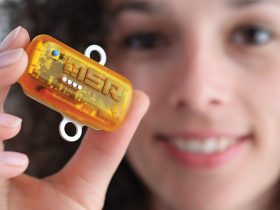

CERN, the European Organization for Nuclear Research, located near Geneva, is one of the largest and most renowned centers for fundamental physics research in the world. Both MSR175plus and MSR175 transport data loggers were used for test shipments of high-sensitivity detector modules from Europe to the U.S., recording shocks in the ±200 g measurement range, air pressure changes, and humidity changes.

CERN, the European Organization for Nuclear Research, located near Geneva, is one of the largest and most renowned centers for fundamental physics research in the world. Here, well over 15000 researchers and staff from a wide range of disciplines are engaged in various tasks of modern particle physics in order to investigate the structure of matter and the fundamental interactions between elementary particles.

This organization has recently become known primarily for the Large Hadron Collider (LHC), which has a circumference of 27 km and uses 9300 magnets to direct the particle beams around the accelerator ring. One of the research tasks being carried out in the LHC is ALICE (A Large Ion Collider Experiment). This is a current experiment in particle physics designed to recreate the state of matter immediately after the Big Bang, called Quark Gluon Plasma (QGP), and it alone employs more than 1000 people.

Monitoring highly sensitive detectors in transit

ALICE has an intensive collaboration with the sPHENIX experiment at BNL (Brookaven National Lab) in the USA. For this experiment, which is concerned with the study ofQGP, ALICE is supplying a total of 84 detector modules based on active monolithic pixel sensors; these are used to observe charged particles produced by the collision of ions at high energy.

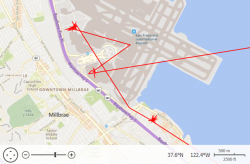

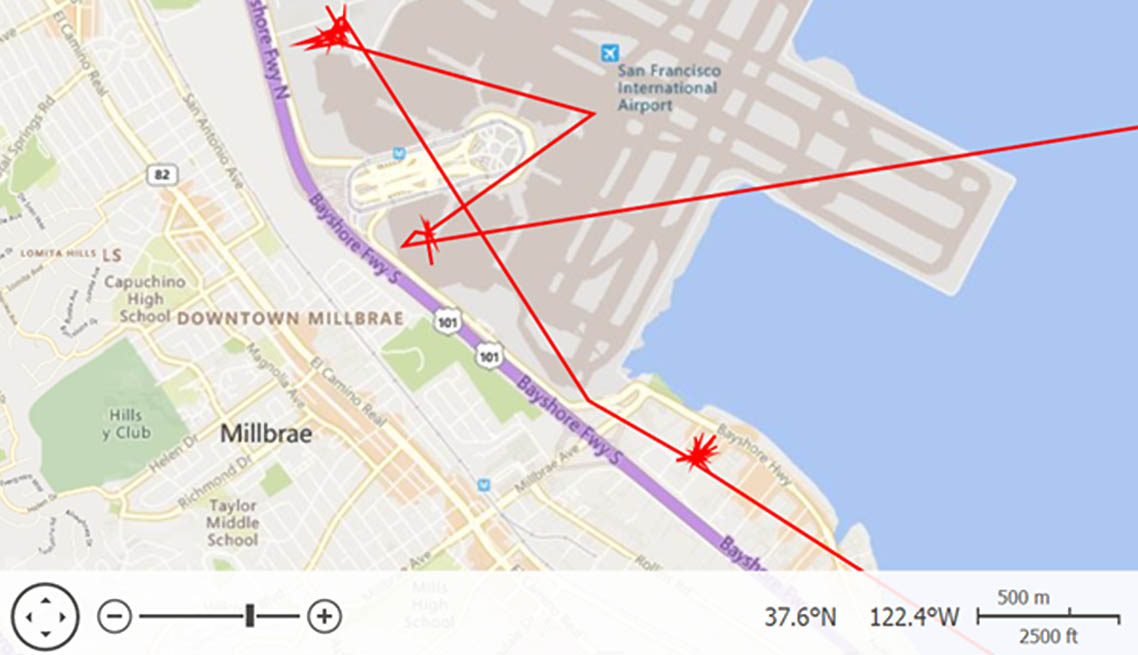

The detector modules are very sensitive to vibrations, shocks or unusual changes in environmental conditions regarding temperature, pressure or humidity. For this reason, the detector modules are transported from Geneva to Laurence Berkeley National Laboratory in California, which is also involved in the sPHENIX project, by air in special suitcase-like containers by hand through several intermediate stations.

However, the current restrictions imposed by COVID-19 entry regulations in the USA make transport by humans impossible, so that a transport company specially certified for the transport of highly sensitive goods is forced to handle the transfer of the modules.

However, trust is good, control is better and so those responsible for the sPHENIX project turned to the measurement technology company MSR Electronics GmbH, based in Seuzach, to place its MSR175 transport data logger and the MSR175plus, which is equipped with GPS tracking, in special transport cases initially for test transfers. For these test transports, however, no real modules were used as test objects, but only simpler sample specimens. The MSR loggers had the task of monitoring the ambient conditions during the transports and recording related measured values as a function of time.

Comprehensive measurement recordings possible

The tamper-proof MSR175 series data loggers act as a kind of “black box”, recording and storing critical transport events that lie above the preset tolerance limit. Both the MSR175 and MSR175plus are equipped with ±15 g and ±200 g 3-axis accelerometers, as well as one each of temperature, humidity, air pressure and light sensors.

The MSR175plus adds a GPS/GNSS receiver, which can be used to locate transport events. In addition, the two logger types differ in their shock measurement modes: while the MSR175 optionally records either ±200 g at 6400 Hz, or ±200 g at 3200 Hz, or ±15 g at 1600 Hz, the newly launched MSR175plus measures simultaneously (±200 g at 6400 Hz and ±15 g at 1600 Hz). This is a decisive advantage in transport monitoring applications where it is not clear from the outset which of the two acceleration sensors should be selected. The danger of not selecting the correct sensor when setting up is thus eliminated.

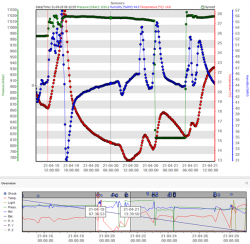

The memory of both logger types is sufficient to record data for days or months. The transport data can be read out via USB. Using evaluation software, conspicuous events can be quickly analyzed and documented as evidence. The recorded measurement data is not only indispensable for clarifying liability and insurance issues in the event of transport damage, they also help to optimize packaging.

In the specific case of the CERN transport of the highly sensitive detector modules from Europe to the USA, both the MSR175plus loggers and the MSR175 loggers were used, recording the shocks in the measuring range ±200 g, changes in air pressure and humidity. The data obtained can be used to improve transport conditions and overall handling, which increases overall transport safety

Conclusion

The MSR175 and MSR175plus data loggers are suitable for universal monitoring of all types of transport. For example, in electronics, medical, automotive, automation or general equipment technology. Due to their compact design, calibrated sensors, large memory capacity and long battery life, they are predestined for long-term monitoring of important physical transport parameters. This is important not least when a cause of damage, a time of damage or a damage location must be determined, for example, to clarify liability issues.

The MSR175 and MSR175plus data loggers are suitable for universal monitoring of all types of transport. For example, in electronics, medical, automotive, automation or general equipment technology. Due to their compact design, calibrated sensors, large memory capacity and long battery life, they are predestined for long-term monitoring of important physical transport parameters. This is important not least when a cause of damage, a time of damage or a damage location must be determined, for example, to clarify liability issues.

You may also be interested in these pages:

- Product overview data loggers for transportation and logistics

- MSR175plus shock data loggers monitor transport of grinding machines

- In space for NASA: MSR165 transport data loggers monitors cargo

- Use of MSR165 data loggers in a CTI research project for risk assessment for shock and vibration immissions

- Wegmüller AG: Transport monitoring with MSR data loggers

- Uroviva Services AG, transport monitoring of highly sensitive medical technology

- Acceleration measurements: Vibration, jolts, shock: Determination of acceleration values with MSR145, MSR165, MSR175 and MSR175plus data loggers

Deutsch

Deutsch