MSR shock data loggers monitor transport of grinding machines

What happens when and where to valuable freight on its way to its destination? With the MSR175plus transport data logger with shock sensors, climate sensors and GPS tracking, it is clearly traceable where the consignment of goods was worldwide. In the event of damage, the recorded data can quickly provide a comprehensive picture of the transport circumstances.

Transport damage is not only expensive, it also damages the image. To prevent this from happening in the first place, a leading global technology provider for gear grinding has its freight monitored with MSR data loggers for quality assurance purposes. The company develops top-class gear grinding machines, 90 percent of which go to the automotive industry.

In a company whose products are almost invariably exported to international markets, monitoring transport is crucial. In production and logistics, it was discovered early on that product complaints were in the vast majority of cases not due to material or production defects, but to damage caused during transport.

Determine transport loads in shipping tests

First and foremost, the logistics manager wanted to optimise the packaging so that transport damage to the freight could be avoided in the first place. To do this, he turned to the Swiss specialist for export packaging, Wegmüller AG from Attikon near Zurich. Wegmüller developed custom-fit wooden packaging and recommended a special desiccant corrosion protection process. In order to prove the flawless effect of the corrosion protection process and the outer packaging, Wegmüller relied on MSR165 data loggers equipped with shock, temperature, humidity, air pressure and light sensors from the Swiss measurement technology company MSR Electronics GmbH for initial test trials back in 2016. Shocks caused by excessively hard impacts and blows during loading, reloading or unloading are generally considered to be the main cause of transport damage. They can have a very negative effect on the mechanical construction of any industrial or consumer item, but are often not visible externally.

Very often, however, goods also suffer rust damage during the journey. Corrosion is caused by moisture, especially temperature fluctuations, which cause condensation to accumulate on metallic surfaces. Wegmüller’s desiccant process keeps the packaged goods in a constantly dry atmosphere. Wegmüller was able to demonstrate with the collected data from the MSR data loggers that the process works perfectly.

Data loggers can detect possible damage at an early stage and reconstruct events.

Using the recorded data of an MSR data logger, it can be recognised beyond doubt after transport whether a product has been exposed to excessive vibrations or environmental stresses and whether it is necessary to check the quality again. To answer the question of where the damage occurred, MSR175plus data loggers with GPS tracking are used in addition to MSR165 data loggers.

The MSR175plus transport data loggers are equipped with two shock sensors (±15 g and ±200 g), one temperature, humidity, pressure and light sensor each, as well as a GPS/GNSS (Global Navigation Satellite System) receiver. The satellite-based position data are stored by the data logger and thus critical transport events can be localised quickly. In the case of insurance or liability issues, the MSR175plus data logger helps to settle claims quickly and easily.

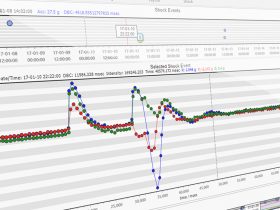

Test trials were conducted to determine where the MSR175plus shock data logger is best mounted. The decision was made in favour of the machine’s grinding head, as impacts occurring there would present particular challenges. Since it is not always clear in advance of a transport which measuring range is required for the acceleration measurements, the parallel shock value recording of the ±200 g sensor at 6400 Hz and the ±15 g sensor at 1600 Hz is used. Light shocks and strong shocks and impacts are thus recorded equally, in all three axes. The higher the recording frequency, the more accurately both the actual course and the peak values are mapped and the more meaningful the data obtained.

The service technician on site dismantles the logger immediately after the arrival of the cargo and sends it back to the head office in the package already supplied. Both the MSR165 and the MSR175plus are approved for air freight. In the case of the MSR175plus data logger, there is also the option of removing the battery for return shipment; depending on country-specific regulations, this may be relevant.

The responsible employee reads the recorded data from the logger via USB and interprets it with the MSR PC software. In addition to the MSR PC software for configuring and evaluating the data, the scope of delivery of the MSR165 and MSR175plus data loggers also includes the “MSR ShockViewer” evaluation software, which specialises in evaluating shock events. If nothing abnormal is detected, the data file is stored for documentation purposes. If a critical event is detected, a fitter is immediately contacted on site to deal with the matter. The data logger is reconfigured and enclosed with the next shipment.

The logistics manager emphasised the preventive effect of the data logger as positive: He noted that care in handling the freight is usually significantly higher when an MSR data logger is on board.

These pages might also be of interest to you:

- Product overview MSR data loggers for transport, logistics

- CERN, European Organisation for Nuclear Research: MSR Data Loggers as Transport Detectives

- Acceleration measurements: Vibration, jolts, shock: Determination of acceleration values with MSR145, MSR165, MSR175 and MSR175plus data loggers

- Use of MSR165 data loggers in a CTI research project for risk assessment for shock and vibration immissions

- Wegmüller AG: Transport monitoring with MSR data loggers

- Uroviva Services AG, transport monitoring of highly sensitive medical technology

- MSR data loggers provide information about transport loads on goods of all kinds

Deutsch

Deutsch