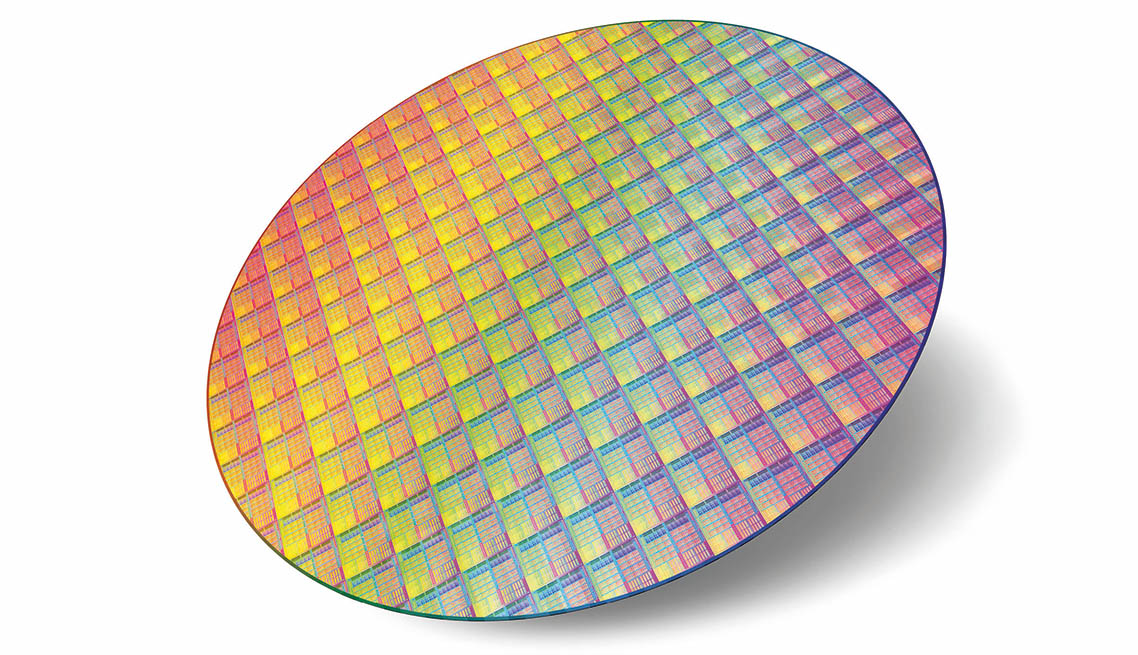

TSMC, Taiwan Semiconductor Manufacturing Company Limited, has been the world’s dedicated semiconductor foundry since 1987. The company uses MSR175plus shock data loggers for monitoring and quality assurance of highly sensitive wafer transports.

Author: Xavier Yangg, Honghong Technology Co., Ltd, a subcompany of Hongke Technology Co., Ltd

In 2023, TSMC served 528 customers and manufactured 11,895 products for various applications covering a variety of end markets including high performance computing, smartphones, the Internet of Things (IoT), automotive, and digital consumer electronics. Annual capacity of the manufacturing facilities managed by TSMC and its subsidiaries exceeded 16 million 12-inch equivalent wafers in 2023. TSMC owns several wafer fabs in Taiwan, China and the USA. In addition, TSCM is investing in the European Semiconductor Manufacturing Company (ESMC) in Dresden, is planning further factories in Arizona (USA) and is building a plant in Kumamoto, Japan.

Significant transport risks for highly sensitive semiconductor components

The transportation of wafers, photomasks or chips in the semiconductor industry, is a critical phase, as these components are very delicate. Various risks can occur that can lead to potential damage.

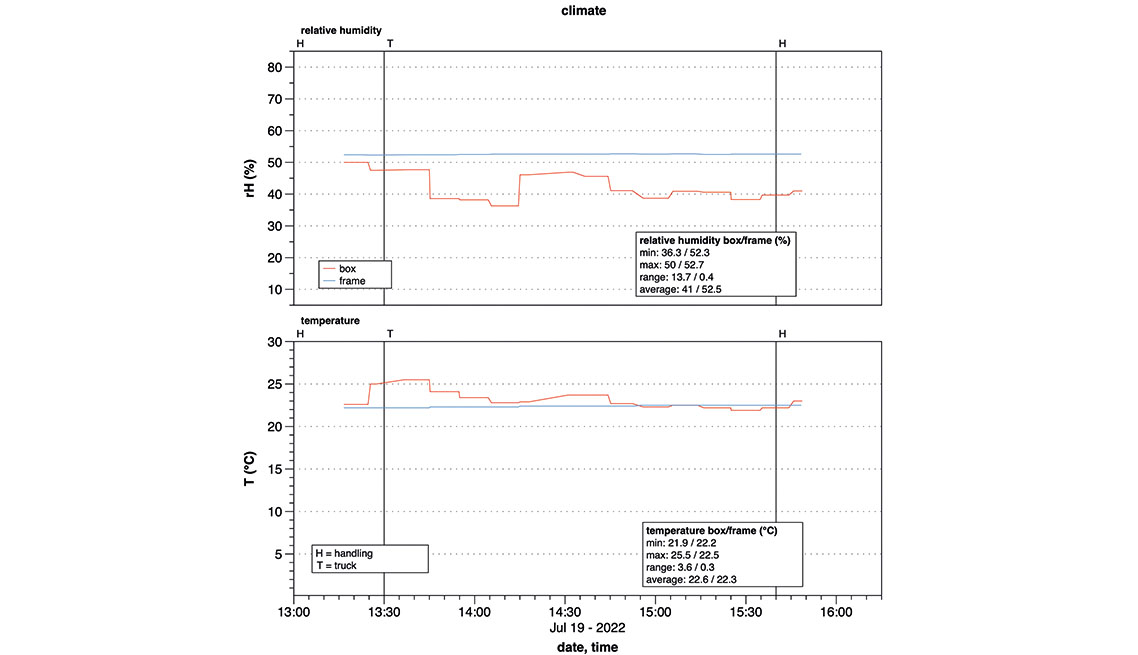

During transportation, shocks, vibrations or improper handling can lead to cracks, scratches or breakages. Wafers, the base material for the production of semiconductor components such as chips and sensors, are extremely thin and react extremely sensitively to mechanical, thermal, chemical and electrostatic influences. Even minimal impurities or irregularities in their surface or structure can have a negative impact on the electrical properties of the components manufactured on them. For this reason, strict protocols are followed in the semiconductor industry to ensure the quality and integrity of the wafers.

Most transport damage caused by mechanical stresses such as shocks, impacts and vibrations is not visible from the outside or at first glance. It is precisely for this reason, as well as for reasons of traceability in the event of liability issues, that it is essential to monitor the transport of highly sensitive goods with a data logger as a travelling companion.

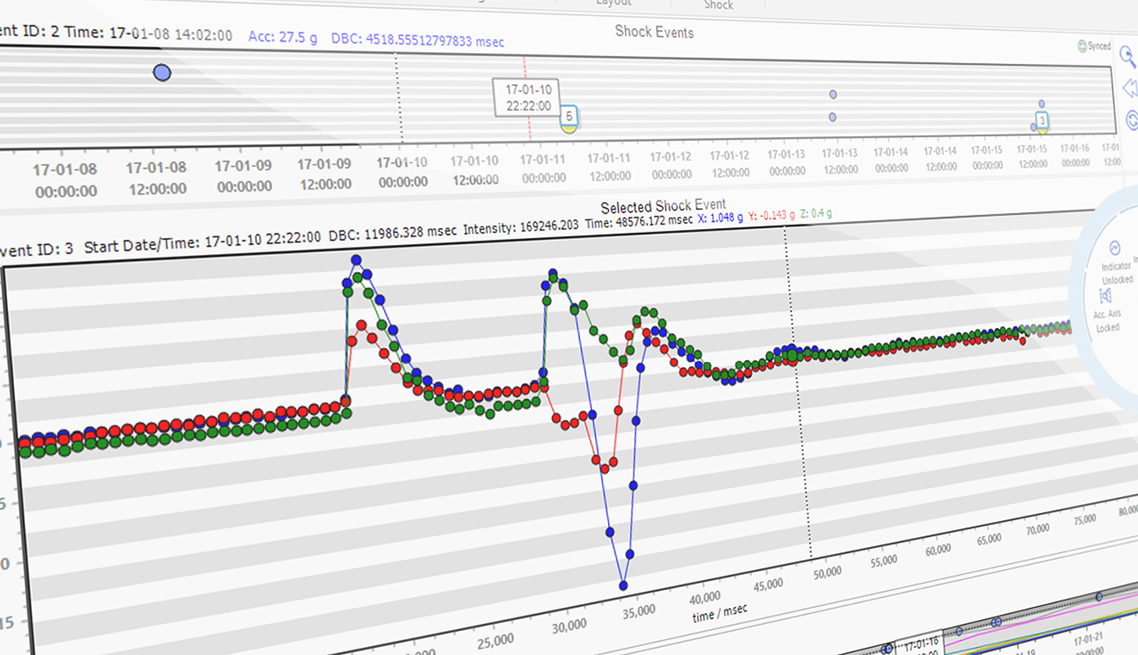

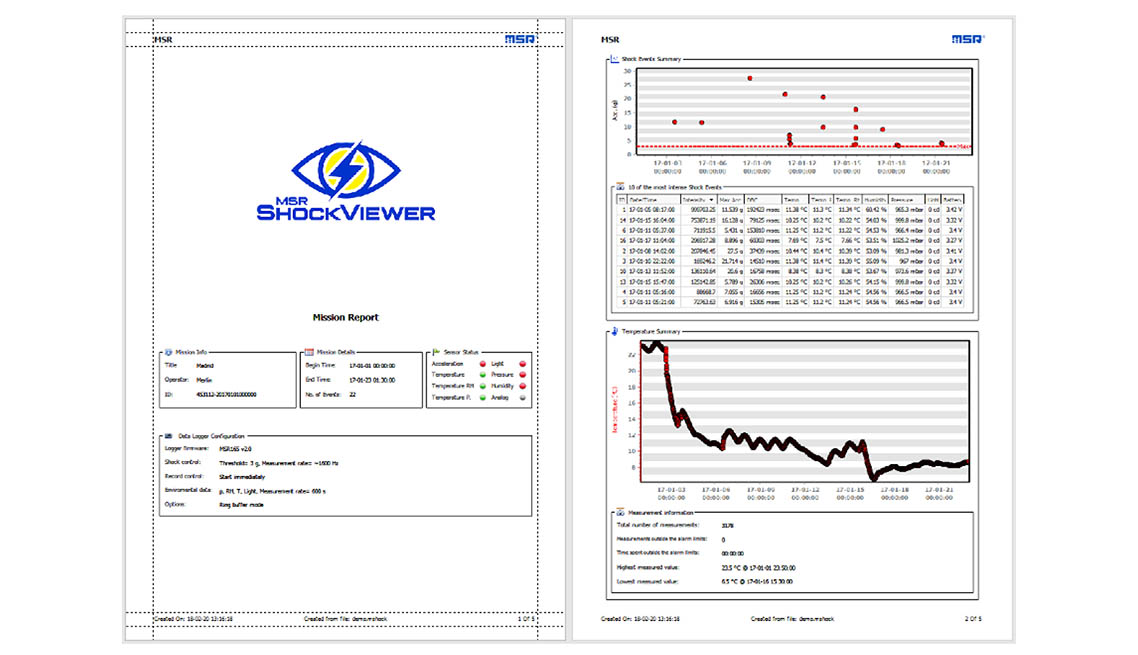

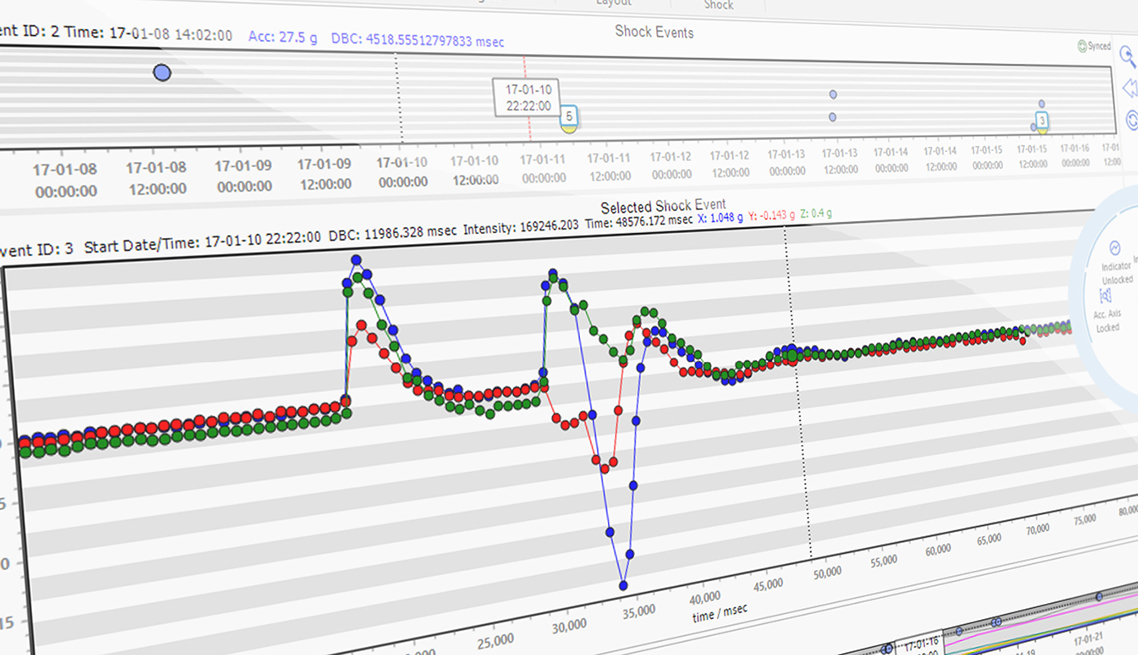

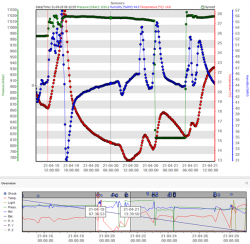

To ensure that the relevant measured values are recorded and stored, it is important to pay attention to the measurement/storage rate, the data storage capacity , the measuring range of the g-force sensor(s), the battery capacity and the robustness when choosing a transport data logger. Equally important is powerful analysis software that is able to process millions of data quickly and determine relevant shock events quickly.

After all, what use is a logger if its storage options are not sufficient for the required tasks or the recorded data is not meaningful and certainly not conclusive? For quality reasons, TSMC has decided to use MSR175 and MSR175plus transport data loggers from the Swiss manufacturer MSR Electronics GmbH.

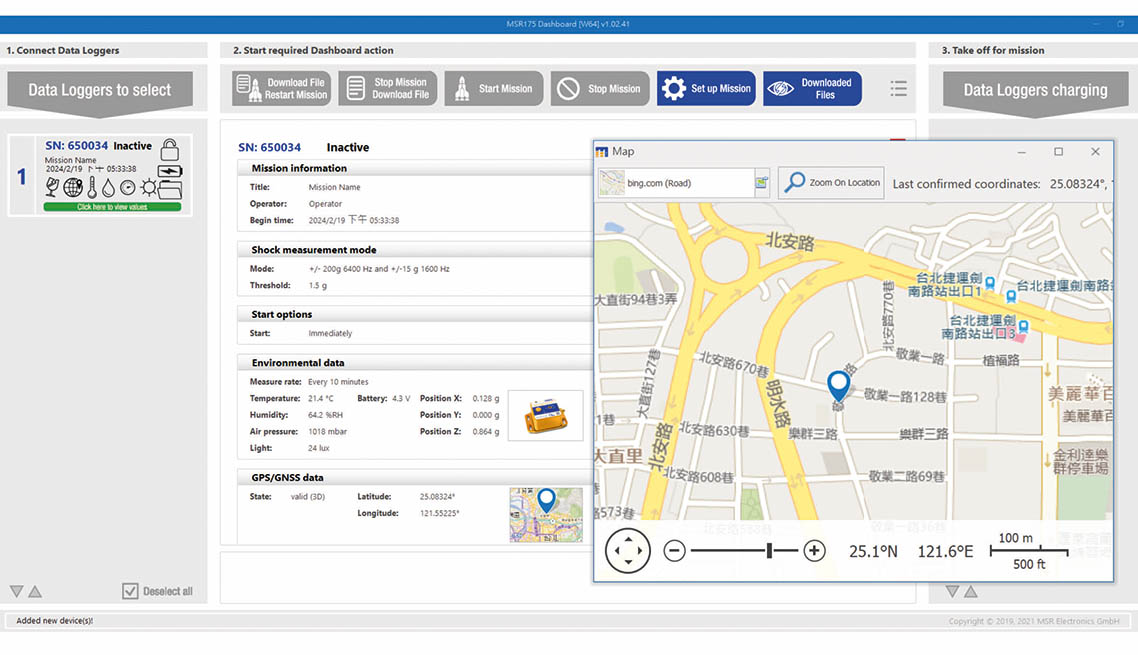

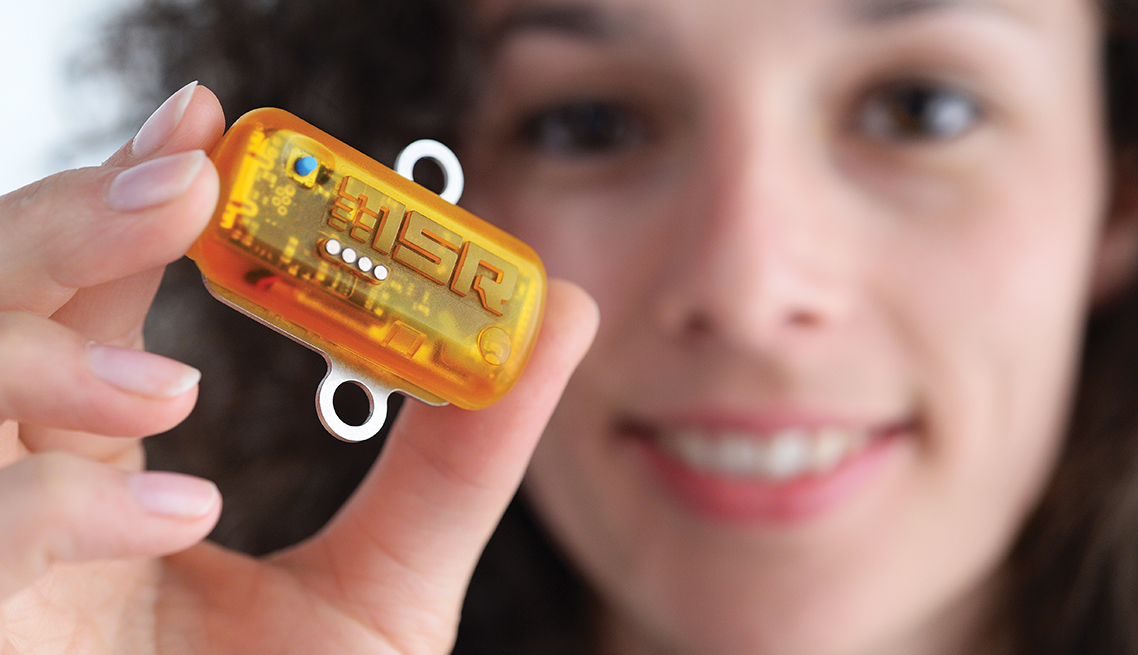

MSR175plus shock and climate data logger detects even concealed transport damage

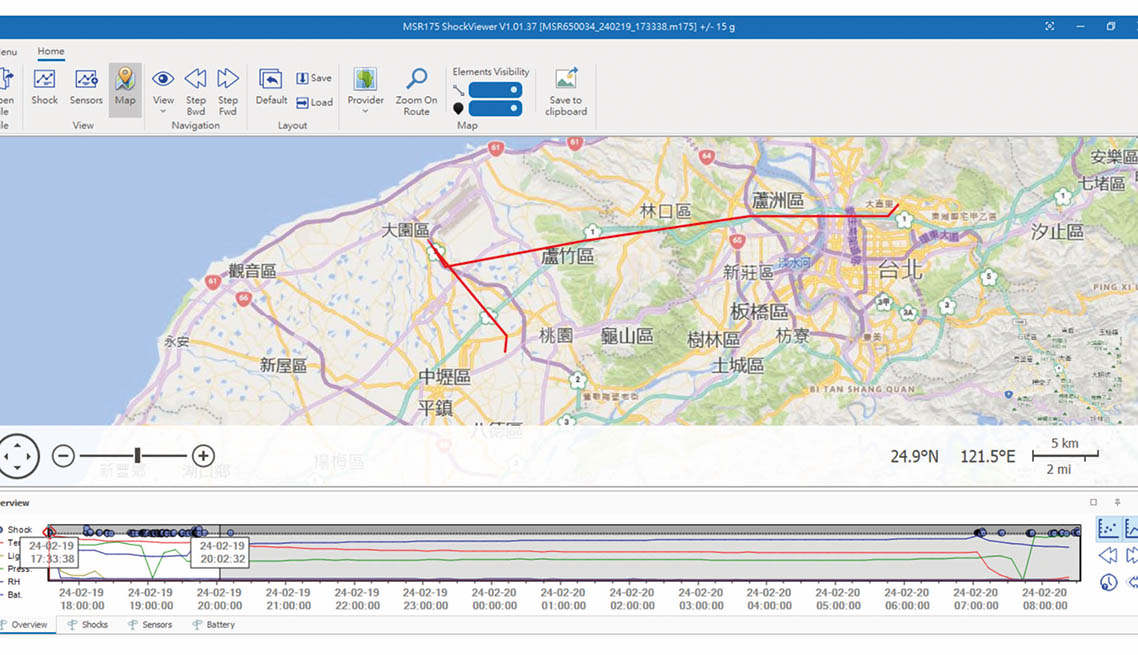

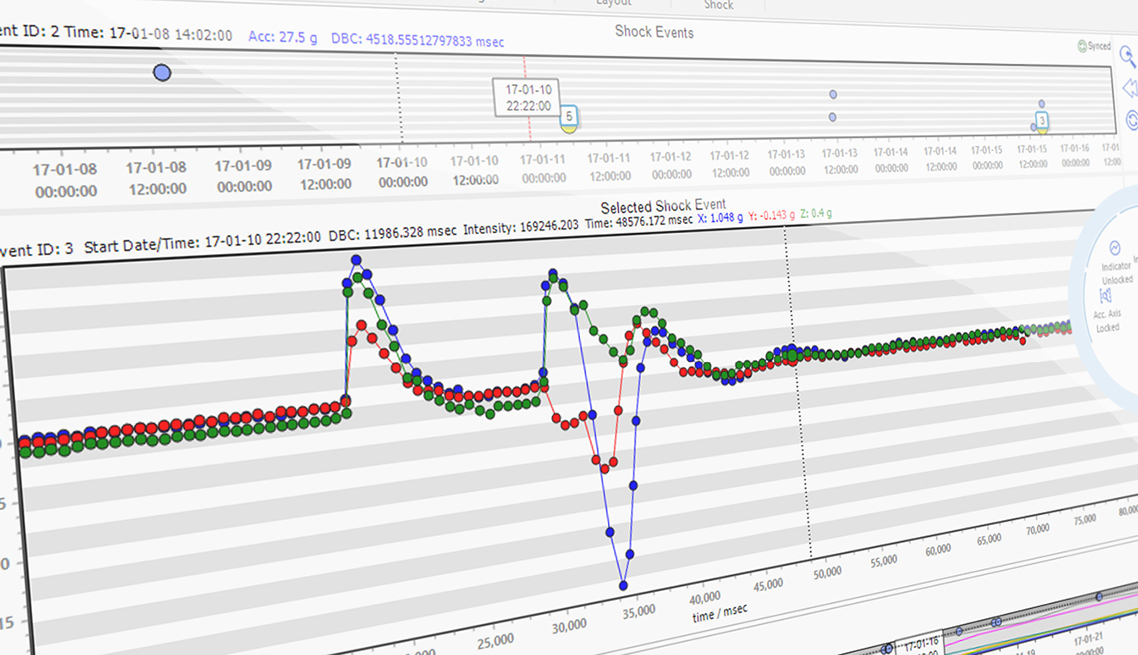

TSMC uses MSR175plus data loggers for instance in the transport between Taiwan province and the United States. As vibrations occur during transportation, the engineers in charge want to understand the actual g-values and define the maximum vibration range. The average round-trip transportation time is approximately 9 days, covering a distance of about 25,000 kilometers. Due to long-distance testing requirements, the high battery capacity and storage characteristics of MSR175plus was one of the main arguments in favour of choosing the MSR175plus. The company had experienced with other data loggers that when recording excessive shock data over a longer period of time, data loss occurred due to insufficient storage capacity. The company no longer wanted to take this risk and therefore opted for MSR data loggers after consulting Hongtronics, a branch of Hongke. The MSR175plus data logger’s memory of 4 million measured values is sufficient to record data for days or months; over 1,000 shock or impact events can be registered.

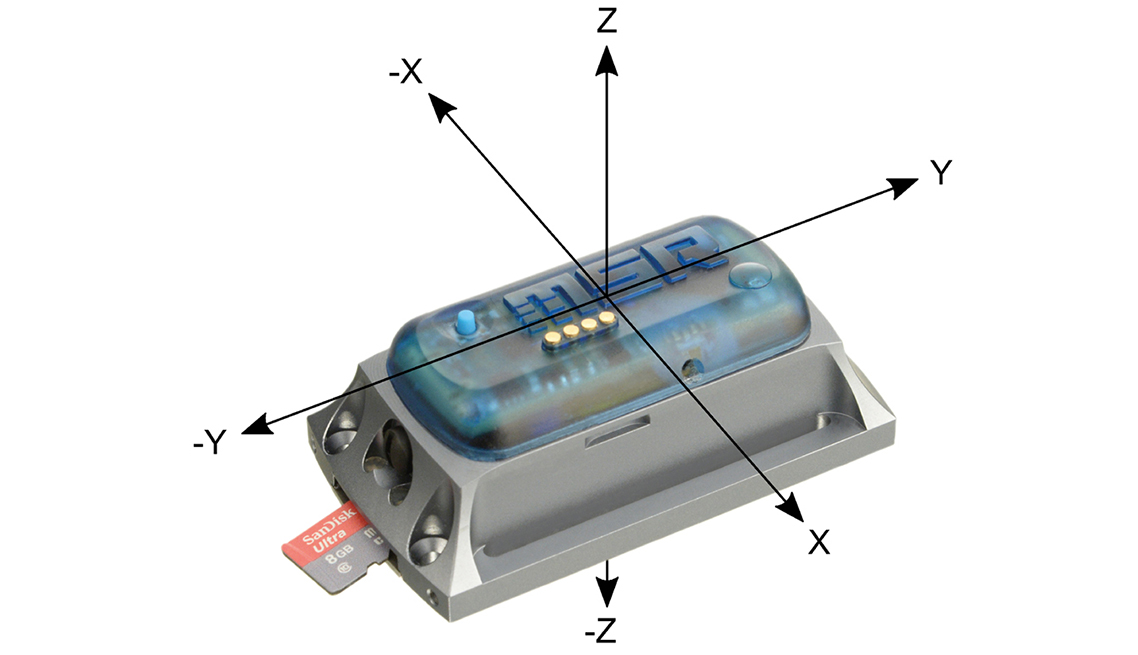

Acceleration sensors simultaneously record ±15 g and ±200 g shock values

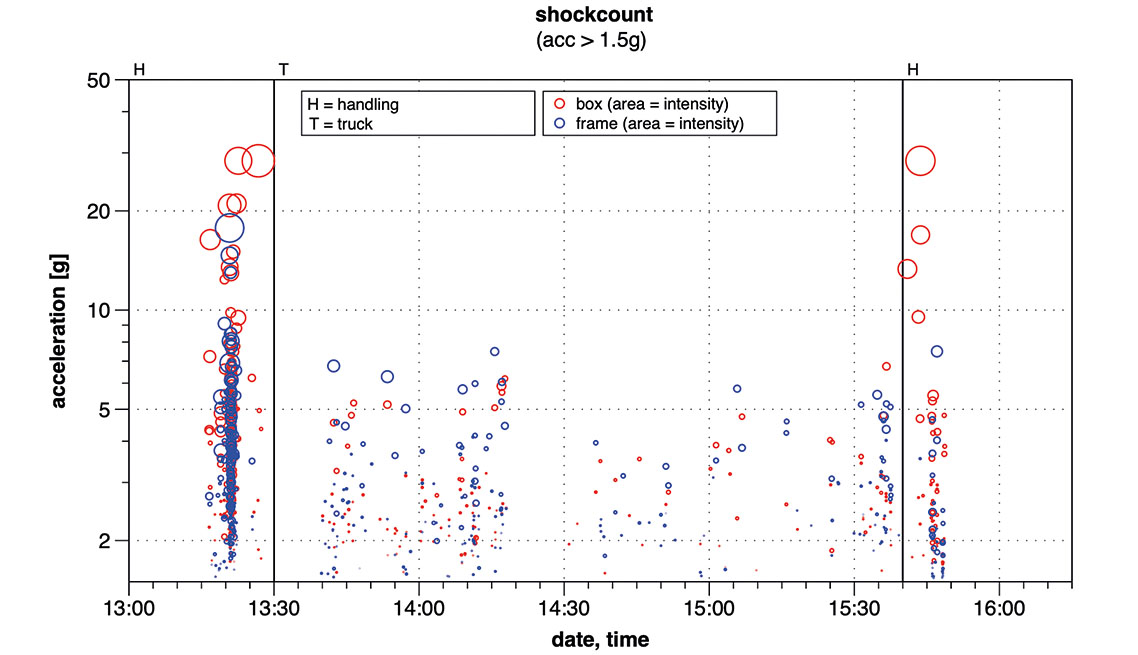

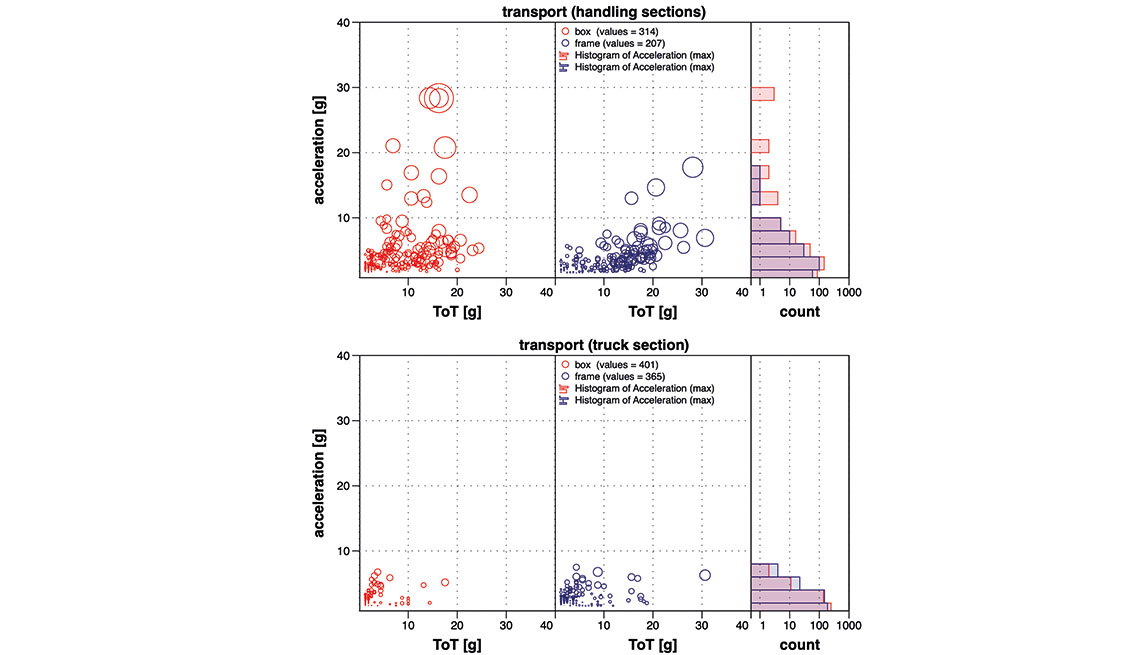

Shocks, often occurring during reloading or unloading in the harbour or during transport, is considered the most common cause of transport damage. Shock events can have a very negative impact on the mechanical construction of any industrial or consumer product, and even more for highly sensitive goods such as wafers and photomasks. Not all damage is caused by the highest shocks. Repeated, less intense shocks can also cause damage, especially to sensitive goods.

The MSR175plus data logger uses highly accurate sensors to monitor and capture potentially damaging events and provides assurance that the specifications of the shipment are met. Thanks to the two simultaneously recording ±15 g and ±200 g acceleration sensors, both light shocks and strong shocks and impacts are detected, delivering unparalleled insights of the transport.

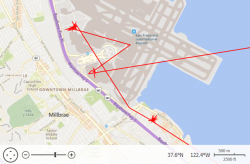

In addition, the MSR175plus data logger measures and stores temperature, humidity, air pressure and light and is equipped with a GPS/GNSS (Global Navigation Satellite System) receiver. The satellite-supported position data is stored by the data logger, allowing the location of a transported item to be quickly determined and documented in the event of a damage.

The 2400 mAh lithium-polymer battery, which can be recharged via USB, ensures that the logger runs for a long time, even with GPS tracking activated.

MSR175plus boasts high precision and reliability, providing detailed data reports and charts for easy analysis and comparison. Its durable casing can withstand the challenges of transportation environments, coupled with a long battery life, ensuring extended monitoring periods. In the event of damage, the logger provides a clear picture of the damaging event including indispensable data to be used in determining liability as well as helping with insurance claims.

Successfully address the challenges of wafer transportation

TSMC has successfully addressed the challenges of wafer transportation and will continue to use MSR data loggers to monitor the vibration and shock values generated during the round-trip transportation of photomasks and wafers between Taiwan province and the United States. TSCM engineers state they highly recommend the use of MSR data loggers to manufacturers or engineers in need of quantifying vibration data.

In conclusion, the MSR175plus is a powerful GPS data logger that offers a comprehensive solution for transportation monitoring. By using MSR175plus, effective management and control of various parameters during transportation can be achieved, ensuring the safety and quality of products.

These pages might also be of interest to you:

- Product overview MSR data loggers for transport, logistics

- CERN, European Organisation for Nuclear Research: MSR data loggers as transport detectives

- Acceleration measurements: Vibration, jolts, shock: Determination of acceleration values with MSR145, MSR165, MSR175 and MSR175plus data loggers

- Use of MSR165 data loggers in a CTI research project for risk assessment for shock and vibration immissions

- Uroviva Services AG, transport monitoring of highly sensitive medical technology

- Orbital Sciences Corp: MSR shock data loggers monitor NASA transport to the International Space Station ISS

Deutsch

Deutsch