MSR165 Data Logger for Investigating the Impacts of Vibrations

Vibrations: where, how and to what extent? Vibration detectives at work.

During electronic functional testing of GPS receiver modules, vibrations of the test apparatus can have a major impact on the measured values. In order to prevent their impact, they must first be localised and quantified. Here, the vibration data loggers of MSR Electronics GmbH can help.

Author: Sahel El Nadeim, Senior Quality Engineer, u-blox

The MSR data loggers are used by u-blox AG, based in Thalwil, Zurich, which is one of the world’s leading providers of position detection and mobile communications technologies for automotive, industrial and consumer goods applications. The chips and modules used in the systems developed for this purpose must be subjected to a variety of practical tests in which vibrations can occur as interference.

Vibrations: where, how and to what extent?

Vibrations have often been used as an explanation for various and initially inexplicable observations in electronic functional testing of GPS modules. But how can this be proven? How much vibration is actually tolerable? And which measures to prevent vibrations are effective?

With the shock and vibration data logger MSR165 of the Swiss company MSR Electronics GmbH, it is quick and easy to ascertain where vibrations occur, as well as the nature of them. In addition, it is possible to quantify how strong the impacts are and how strong they are actually permitted to be before the measurement is impaired.

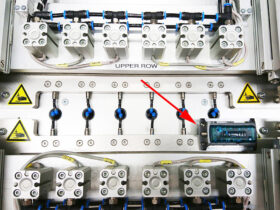

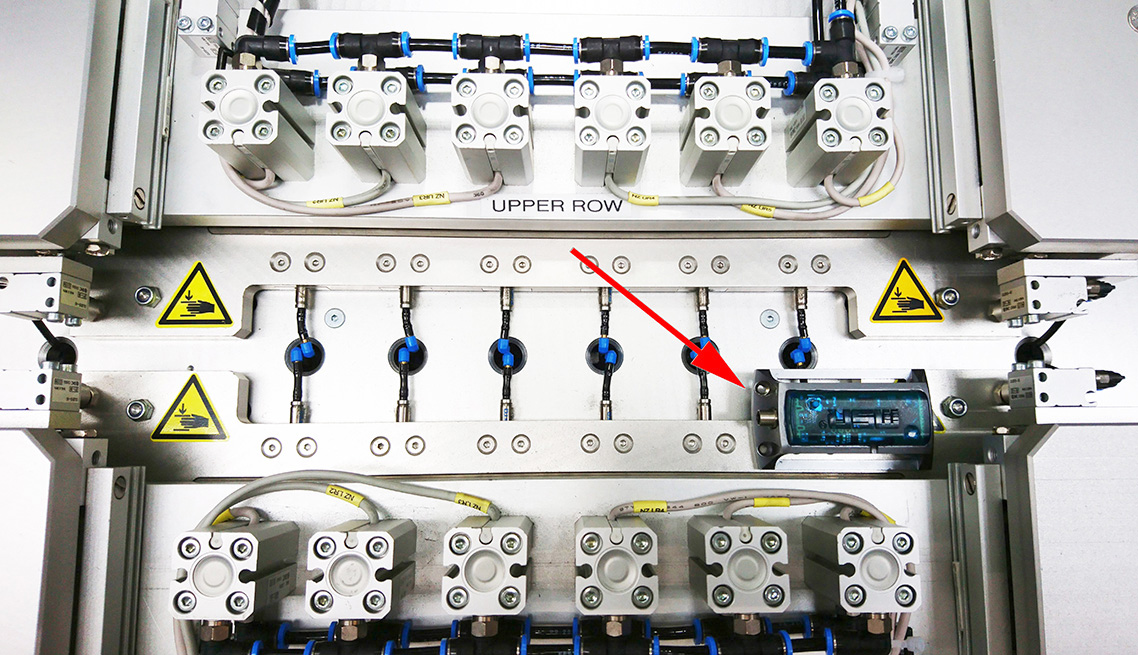

The test system used consists of two separate rows of module fixtures, one of which is being tested while the other is being loaded or unloaded. Robot arms insert the modules to be tested individually into the fixtures (image 1), which are then closed with a compressed air device for the electronic functional test. After the test, the fixtures are opened again by means of compressed air and the modules are removed by the robot arm.

All these mechanical processes generate vibrations with different frequencies and amplitudes, which occur at different points and to different degrees in the respective axis directions. Some of the electronic measurements carried out can be strongly negatively influenced by certain forms of vibrations, since the modules contain vibration-sensitive components such as quartz crystals for oscillators. Since modules are tested in one test fixture while at the same time, the other test fixture is being filled/emptied or opened/closed, the vibrations of one series of fixture can affect the measurement results of the other series.

All these mechanical processes generate vibrations with different frequencies and amplitudes, which occur at different points and to different degrees in the respective axis directions. Some of the electronic measurements carried out can be strongly negatively influenced by certain forms of vibrations, since the modules contain vibration-sensitive components such as quartz crystals for oscillators. Since modules are tested in one test fixture while at the same time, the other test fixture is being filled/emptied or opened/closed, the vibrations of one series of fixture can affect the measurement results of the other series.

Miniature data loggers provide good detective services

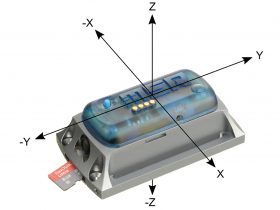

The MSR165 miniature data loggers of the Swiss technology company MSR Electronics GmbH (image 2), which are used to record the vibrations in the series of module fixtures of the test systems, specialise in applications for recording shocks and vibrations. Their sensor technology core element is a high resolution 3-axis digital accelerometer. With this sensor technology element, these loggers are capable of recording shock loads and vibrations of ±15 g in the three axes up to 1,600 times per second; however, an extended working range of ±200 g (g = acceleration of gravity 9.81 m/s2) is also available. The latter working range is useful if stresses are to be recorded, where very large forces occur suddenly. At the same time as recording vibrations, the temperature, humidity, pressure and light intensity can be measured and recorded.The digital 3-axis acceleration sensor starts recording data either when an acceleration threshold is exceeded or at a time set by the user

The MSR165 miniature data loggers of the Swiss technology company MSR Electronics GmbH (image 2), which are used to record the vibrations in the series of module fixtures of the test systems, specialise in applications for recording shocks and vibrations. Their sensor technology core element is a high resolution 3-axis digital accelerometer. With this sensor technology element, these loggers are capable of recording shock loads and vibrations of ±15 g in the three axes up to 1,600 times per second; however, an extended working range of ±200 g (g = acceleration of gravity 9.81 m/s2) is also available. The latter working range is useful if stresses are to be recorded, where very large forces occur suddenly. At the same time as recording vibrations, the temperature, humidity, pressure and light intensity can be measured and recorded.The digital 3-axis acceleration sensor starts recording data either when an acceleration threshold is exceeded or at a time set by the user

Thanks to the memory function, which can be expanded to over one billion data records by means of an SD card, the MSR165 can record the data live in production offline, i.e. without a cable connection to the measuring computer. Depending on the battery fitted, operation could also be carried out over many months. The vibration data is then analysed using a PC by means of software that is user-friendly, yet provides detailed analyses.

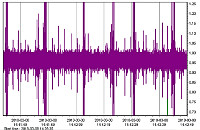

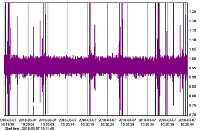

In In the described case the data collected showed that in one series of fixtures, vibrations that occur during loading and unloading of the other series of fixtures can be measured during the electronic testing of the modules. The exact amplitude, frequency and vibration axis can be identified. This measurement required a high sampling rate, which is available with the MSR165 at 1600 Hz (image 3).

A previous measurement, in which the MSR165 was also used as a vibration logger, confirmed that such vibrations have a negative effect on the measured parameters. Using vibration-reducing measures, test failures as a result of vibrations can now be minimised (image 4).

A previous measurement, in which the MSR165 was also used as a vibration logger, confirmed that such vibrations have a negative effect on the measured parameters. Using vibration-reducing measures, test failures as a result of vibrations can now be minimised (image 4).

These pages might also be of interest to you:

- Configure your own custom MSR165 variant here!

- Product overview MSR data loggers for the manufacturing industry

- Muller Martini: Defective sensors – finding the cause with MSR165 data logger

- Otto Bock Mobility Solutions: MSR data loggers record usage behaviour of wheelchair users

- IGR: MSR data loggers determine load values in filling plants

- Determination of acceleration values with MSR145, MSR165, MSR175 and MSR175plus data loggers

Deutsch

Deutsch