MSR145WD Wireless Data Logger for Lantal Textiles AG

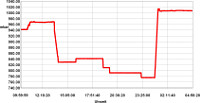

Measured data from the aircraft seat

Mini data loggers are primarily known for their use in monitoring machines, systems and transports. However, data loggers can also be highly beneficial in other applications, for instance when developing new generations of aircraft seat components.

As a starting point, aircraft seats must be very comfortable for people, as well as easy to clean, of a high quality and mechanically stable. However, there is another important point: They must also be very light as every additional kilogramme of mass means higher operating costs due to greater jet fuel consumption and therefore higher CO2 emissions. On these grounds, all seat manufacturers in the aviation industry are extremely interested in optimising the ergonomic aspects and reducing the weight of the seats further.

Great weight saving can be achieved

The Swiss Lantal Textiles AG has worked in this sector for many years. Lantal is the leader in the design, manufacture and marketing of textiles and services for international air, bus and rail traffic. A few years ago this company developed its so-called “Pneumatic Comfort System”. It is based on the principle that air-filled cushions replace conventional seat foams. This ensures increased adaptive comfort and a reduced seat weight, meaning a saving of approximately 1.5 to 3 kg of conventional polyurethane foam for each business class seat and approximately 3 to 5 kg for each first class seat. In addition, these cushions have an extended range of functions.

Due to the air chambers, the pressure is distributed optimally and air passengers are able to modify the firmness of the seat cushion to their personal preferences. Both in the sitting and lie-flat positions, the air-filled cushion automatically adjusts itself to the desired conditions; if nothing else, these are potential marketing points for the airlines. Of course, this requires a sophisticated pressure control system that, in spite of the changing cabin pressure, maintains this passenger comfort by means of appropriate pumps and valves. The Pneumatic Comfort System should operate completely maintenance-free, meaning that the operation of the cushion should remain unchanged throughout its service life. Aircraft cushions of this design are already being used by a multitude of international airlines, primarily in first and business class cabins.

Mini loggers investigate the pneumatic control technology

The Swiss company is using the MSR145WD wireless data loggers of MSR Electronics GmbH which is also based in Switzerland, for the further development and long-term tests of the corresponding pneumatic control technology. These mini data loggers, which are the size of a thumb, are able to record and store the parameters of temperature, humidity, pressure, light intensity and acceleration/location by means of internal sensors in freely adjustable scanning intervals. An OLED colour display shows the parameter developments. These loggers are powered by high-capacity batteries and are capable of storing approximately 1 million recorded values, which can be read out via USB on the one hand and wirelessly via the Bluetooth Low Energy wireless standard on the other hand. The Lantal Company utilises the latter transmission option to check the pressure conditions in the pneumatic cushions on the test bench, using the mini data loggers. The company uses over a dozen of these loggers in its research laboratories.

The Swiss company is using the MSR145WD wireless data loggers of MSR Electronics GmbH which is also based in Switzerland, for the further development and long-term tests of the corresponding pneumatic control technology. These mini data loggers, which are the size of a thumb, are able to record and store the parameters of temperature, humidity, pressure, light intensity and acceleration/location by means of internal sensors in freely adjustable scanning intervals. An OLED colour display shows the parameter developments. These loggers are powered by high-capacity batteries and are capable of storing approximately 1 million recorded values, which can be read out via USB on the one hand and wirelessly via the Bluetooth Low Energy wireless standard on the other hand. The Lantal Company utilises the latter transmission option to check the pressure conditions in the pneumatic cushions on the test bench, using the mini data loggers. The company uses over a dozen of these loggers in its research laboratories.

Accurate recording of pressure values

During the respective tests, the internal pressure of the aircraft must also be taken into account as the air pressure in the cushions has to be readjusted in line with the ambient air pressure, which changes during the take-off, landing and cruise flight. When developing the entire pneumatics, electronics and the corresponding control technology, it is particularly important that the pressure values in the cushions can be recorded together with the temperature at a high resolution; this is ensured by means of the internal sensors with a range of 10 to 2000 mbar and a measuring accuracy of ±2 mbar.  The average internal pressure of the cabin during a transatlantic flight is approximately 900 mbar – during the cruise flight at high altitudes it is reduced significantly to approximately 780 mbar – therefore the pressure differential is more than 230 mbar as the normal pressure on Earth’s surface is approximately 1013 mbar. The internal pressure in the seat cushions must be readjusted in line with these differences in pressure, which is tested on the test bench by means of the loggers. The relative humidity of 0 % to 100 % and the 3-axis acceleration within the range of ±15 g are further parameters that are of interest for tests of this nature. Within this context, crash tests are also performed by means of MSR loggers; in the process, all pressure values and other physical parameters that can be stored by the loggers are logged with very high sampling rates. Thanks to their mechanical stability, these mini loggers withstand even these “tough” series of tests without sustaining any mechanical or electrical damage. Thanks to their sturdiness, the loggers can also be used under very unfavorable ambient conditions, for instance in the transport and logistics industry, in automotive engineering and in all the different areas of application within machine building and plant engineering, as they are specified for a temperature range from -20 to +65 °C.

The average internal pressure of the cabin during a transatlantic flight is approximately 900 mbar – during the cruise flight at high altitudes it is reduced significantly to approximately 780 mbar – therefore the pressure differential is more than 230 mbar as the normal pressure on Earth’s surface is approximately 1013 mbar. The internal pressure in the seat cushions must be readjusted in line with these differences in pressure, which is tested on the test bench by means of the loggers. The relative humidity of 0 % to 100 % and the 3-axis acceleration within the range of ±15 g are further parameters that are of interest for tests of this nature. Within this context, crash tests are also performed by means of MSR loggers; in the process, all pressure values and other physical parameters that can be stored by the loggers are logged with very high sampling rates. Thanks to their mechanical stability, these mini loggers withstand even these “tough” series of tests without sustaining any mechanical or electrical damage. Thanks to their sturdiness, the loggers can also be used under very unfavorable ambient conditions, for instance in the transport and logistics industry, in automotive engineering and in all the different areas of application within machine building and plant engineering, as they are specified for a temperature range from -20 to +65 °C.

Data transfer to the cloud via Bluetooth and the mobile network

During the Lantal tests, the parameters are read out either wirelessly via Bluetooth Low Energy (BLE) or – depending on the test set-up – wired via USB. Generally the BLE short-range radio technology is an advantage for applications where measured data must be monitored from locations that are difficult to access, for instance in other sectors of industry from rotating machine parts. The BLE wireless standard enables the user to transmit and record data irrespective of the location within a 20 m radius.

During the Lantal tests, the parameters are read out either wirelessly via Bluetooth Low Energy (BLE) or – depending on the test set-up – wired via USB. Generally the BLE short-range radio technology is an advantage for applications where measured data must be monitored from locations that are difficult to access, for instance in other sectors of industry from rotating machine parts. The BLE wireless standard enables the user to transmit and record data irrespective of the location within a 20 m radius.

In order to be even more independent from the location and to be able to read out the measured values worldwide, MSR Electronics has developed its own cloud application: The measured values transmitted via Bluetooth from the data logger to a nearby mobile network interface are then sent from this mobile network gateway to the MSR SmartCloud, where they can be retrieved from any location in the world, protected by a password. By means of the MSR DataLogger Smartphone app, data recordings can be started, stopped, read out and sent to the MSR SmartCloud at any time. An alarm function is also available in this cloud system.

Therefore, with this application in aeronautical engineering, the mini data loggers show that they can be used in a wide range of metrological applications that exceed machine and transport monitoring or logistics – laboratory and test bench measurement technology are further areas of application. Similar loggers are already being used to record mechanical loads during space flights.

Deutsch

Deutsch